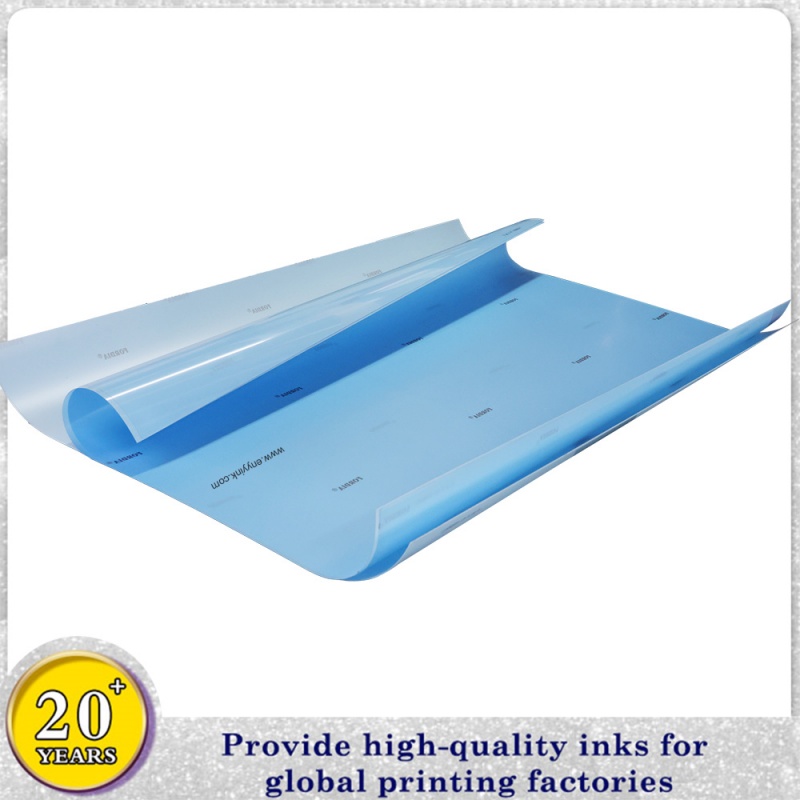

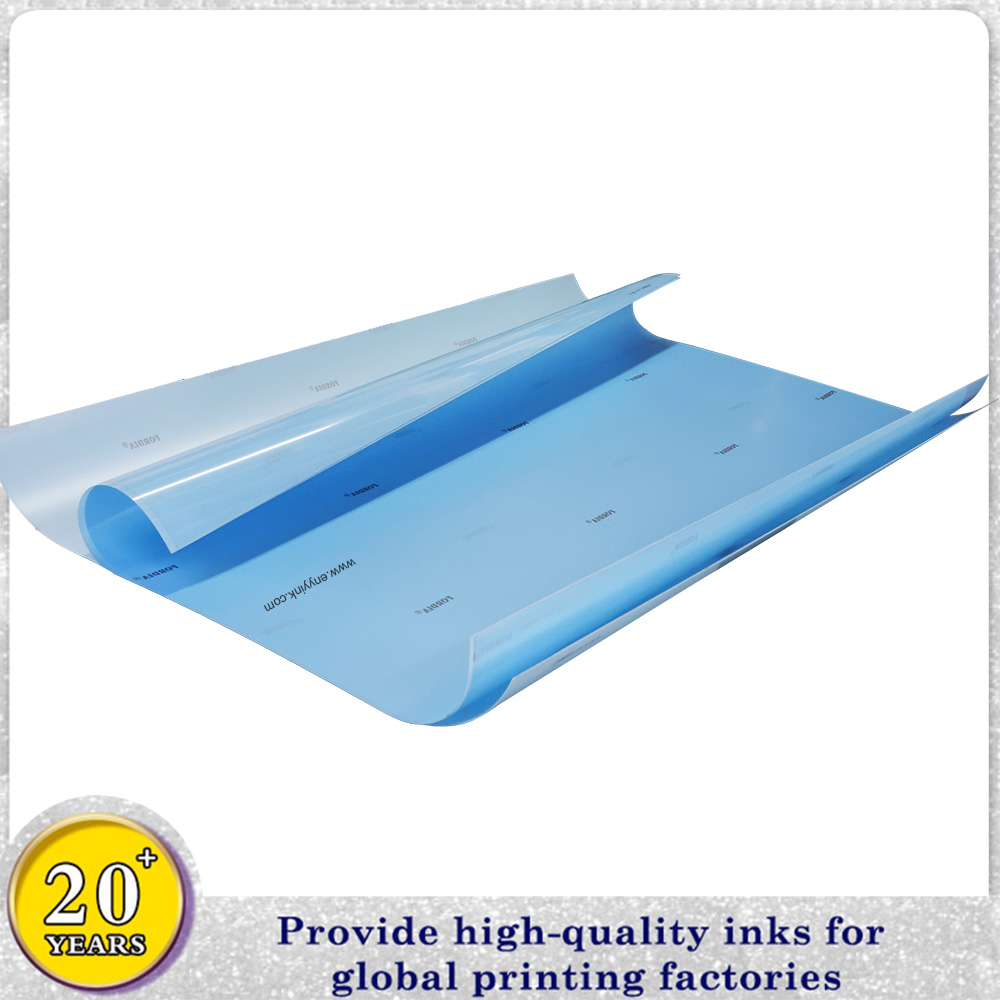

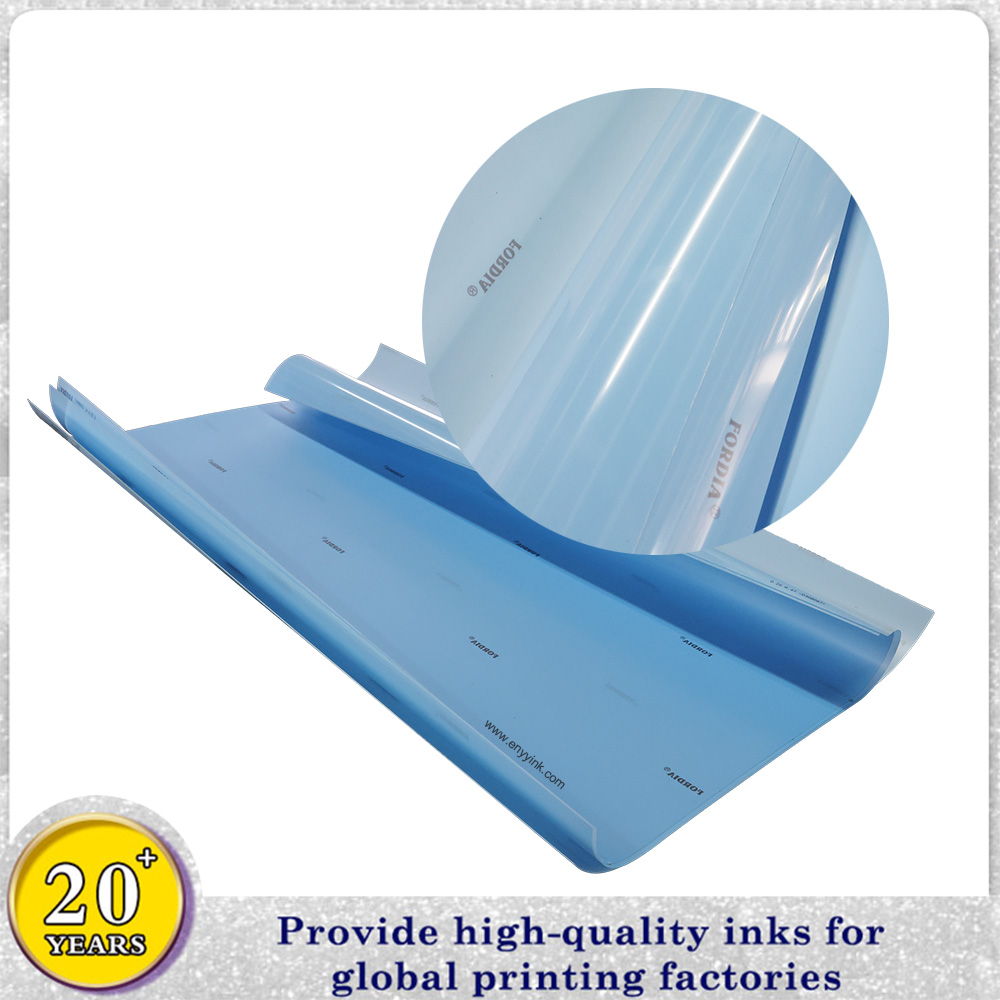

Printing Machine Underlay Film (Base Cushion Sheet)

Brand EISI

Product origin Guangzhou,China

Delivery time 3-5 Days

Supply capacity 10000 pcs

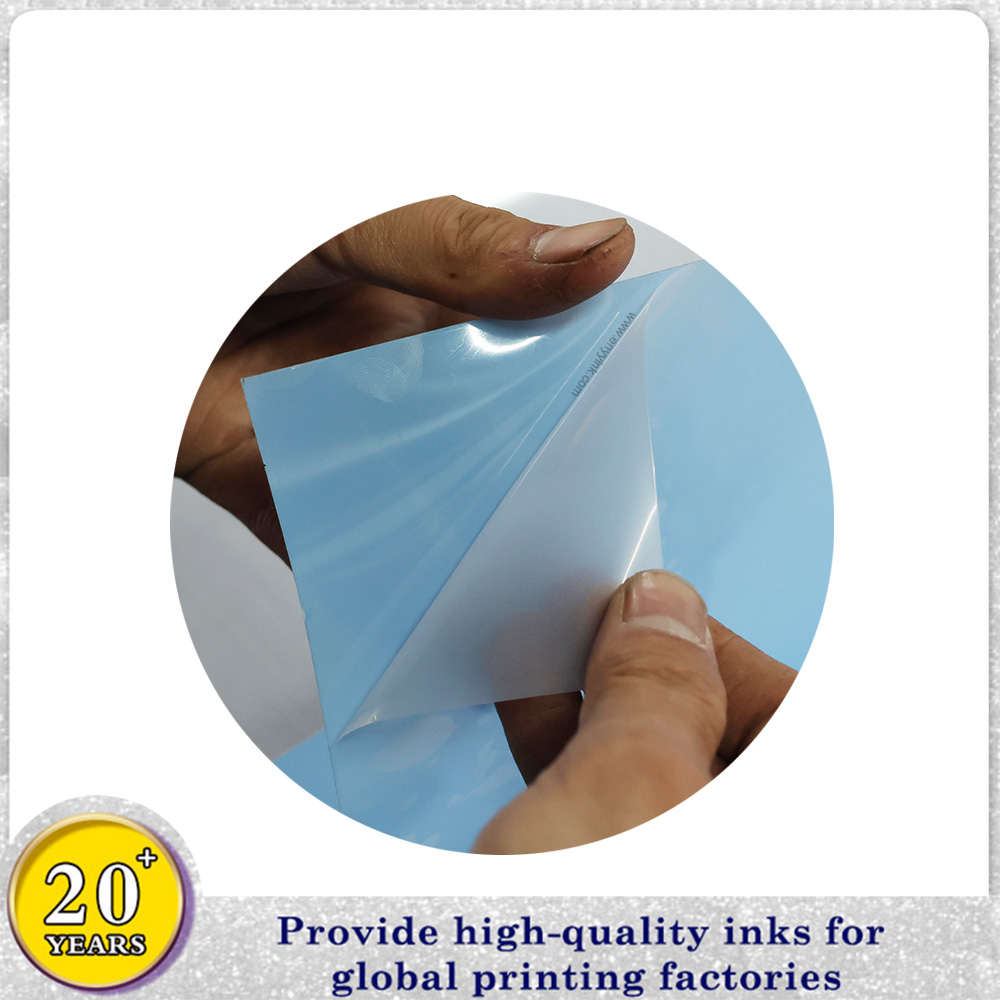

The underlay film (also known as printing machine cushion sheet or base pad) is a high-precision shock-absorbing lining material used in offset presses, die-cutting machines, and other printing equipment. Installed beneath the plate cylinder or impression cylinder, it serves to regulate pressure, compensate for plate thickness variations, protect machinery, and enhance print quality.

Product Overview

The underlay film (also known as printing machine cushion sheet or base pad) is a high-precision shock-absorbing lining material used in offset presses, die-cutting machines, and other printing equipment. Installed beneath the plate cylinder or impression cylinder, it serves to regulate pressure, compensate for plate thickness variations, protect machinery, and enhance print quality.

Key Features

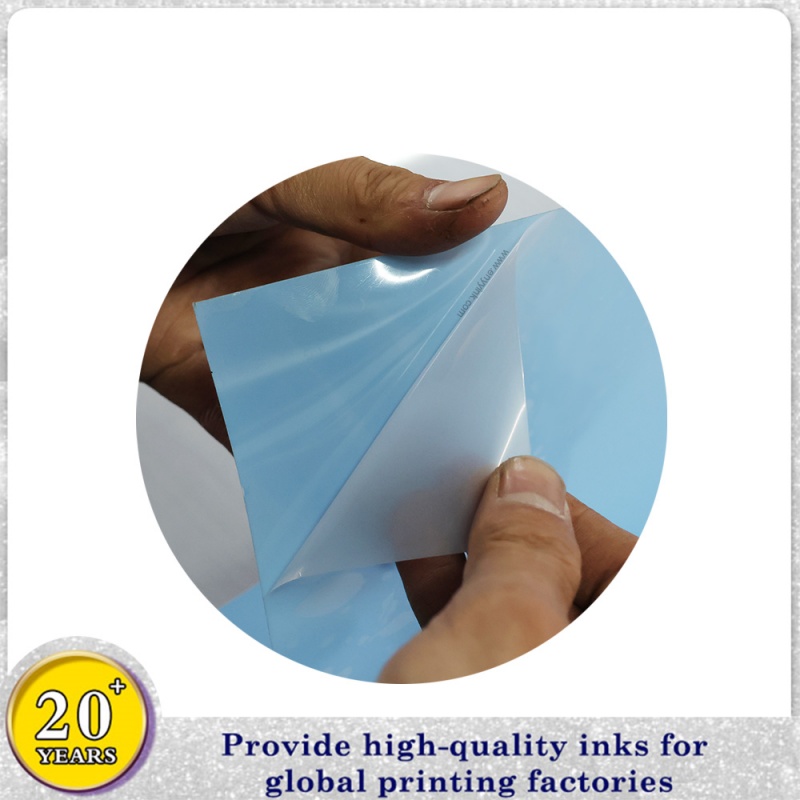

High Elasticity & Pressure Resistance

Made of polyurethane (PU) or specialty rubber, offering superior elasticity to withstand prolonged high-pressure printing and prevent cylinder deformation.

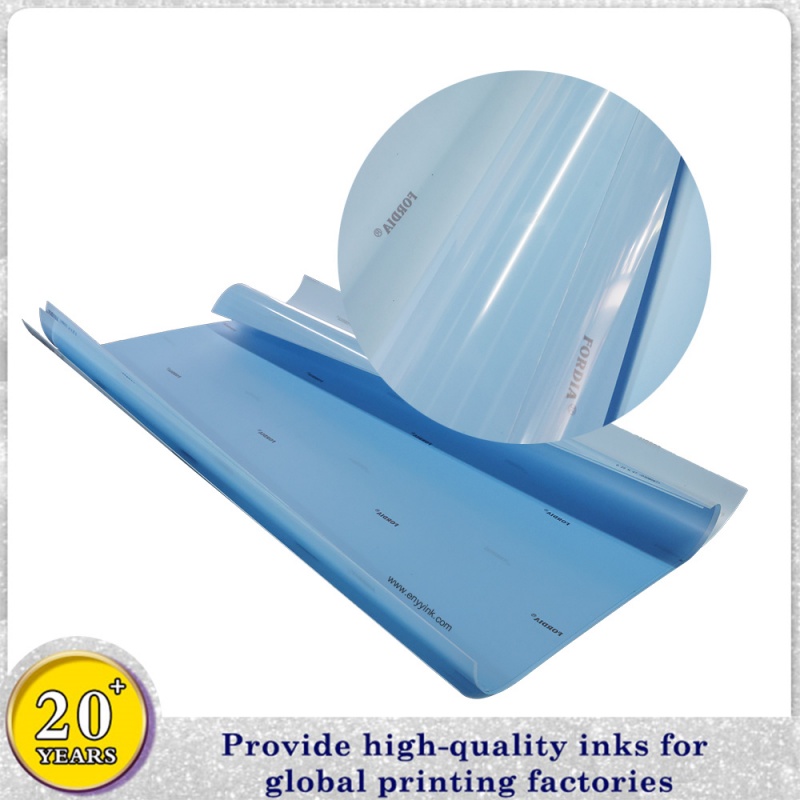

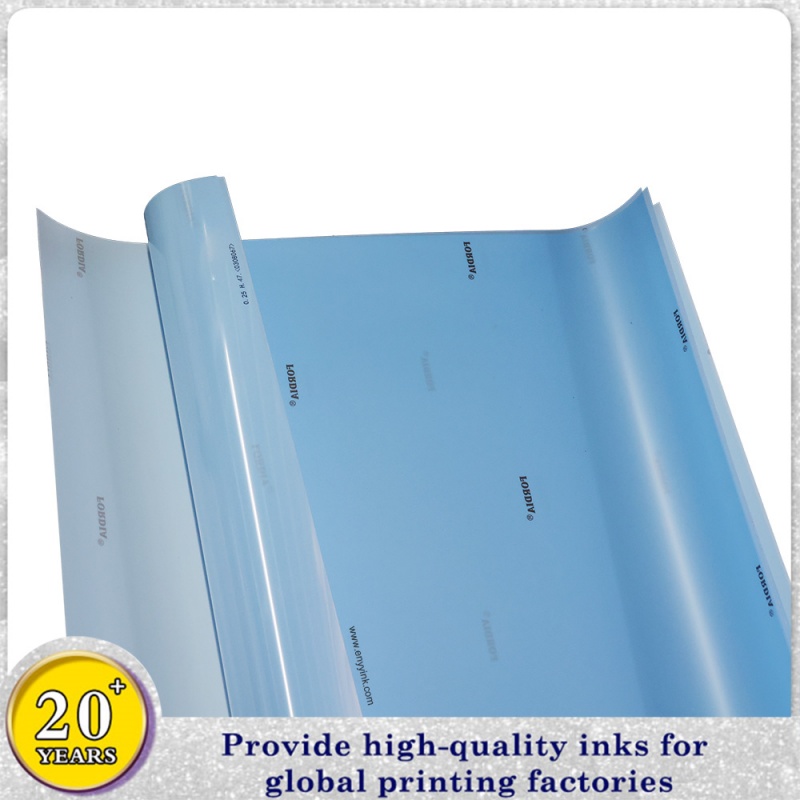

Precision Thickness Control

Thickness range: 0.1mm–1.0mm (customizable), with ±0.02mm tolerance for uniform printing pressure.

Wear & Aging Resistance

Surface-hardened treatment resists ink and dampening solution corrosion, ensuring long service life (up to millions of impressions).

Anti-Slip & Vibration Damping

Features self-adhesive backing or anti-slip texture for secure installation; effectively absorbs machine vibrations to reduce dot blurring.

Broad Compatibility

Compatible with mainstream offset presses from Heidelberg, Roland, Komori, Beiren, and others.

Technical Specifications

| Parameter | Standard Value |

|---|---|

| Material | Polyurethane (PU) / Synthetic Rubber |

| Thickness | 0.1mm, 0.2mm, 0.3mm, 0.5mm, 1.0mm (customizable) |

| Hardness (Shore A) | 70°–90° (selectable per pressure requirements) |

| Temperature Range | -20℃–120℃ (no deformation) |

| Color | Transparent/White/Gray (optional) |

Primary Applications

Offset Press Cushioning:

Used under plate or blanket cylinders to compensate for plate thickness variations, preventing uneven pressure-induced issues like scumming or dot distortion.

Die-Cutting Machine Buffer Pad:

Protects cutting dies from impact damage, extending mold lifespan.

Embossing/Stamping Machines:

Serves as a base pad to enhance dimensional embossing effects.

Advantages Over Traditional Lining Materials

| Feature | Underlay Film | Kraft Paper/Plastic Sheets |

|---|---|---|

| Precision | Uniform thickness (±0.02mm) | Prone to moisture warping, high variability |

| Durability | Pressure- and wear-resistant, long lifespan | Fragile, requires frequent replacement |

| Print Quality | Even pressure, sharp dots | Risk of scumming/ghosting |

Selection & Installation Guide

Machine Compatibility:

Confirm cylinder type (plate/blanket) and required thickness.

Pressure Calibration:

Post-installation pressure adjustment recommended (use a pressure gauge).

Replacement Cycle:

Regular surface wear inspection (typically replace every 6–12 months).

Customization Available: Special sizes, hardness levels, or adhesive backing (e.g., high-temperature/high-rebound variants).

This product is engineered for printing equipment maintenance and print quality optimization, tailored for printing houses, packaging manufacturers, and machine service providers. For datasheets or samples, contact us!

Note: Terminology adapted to global printing industry standards for clarity.