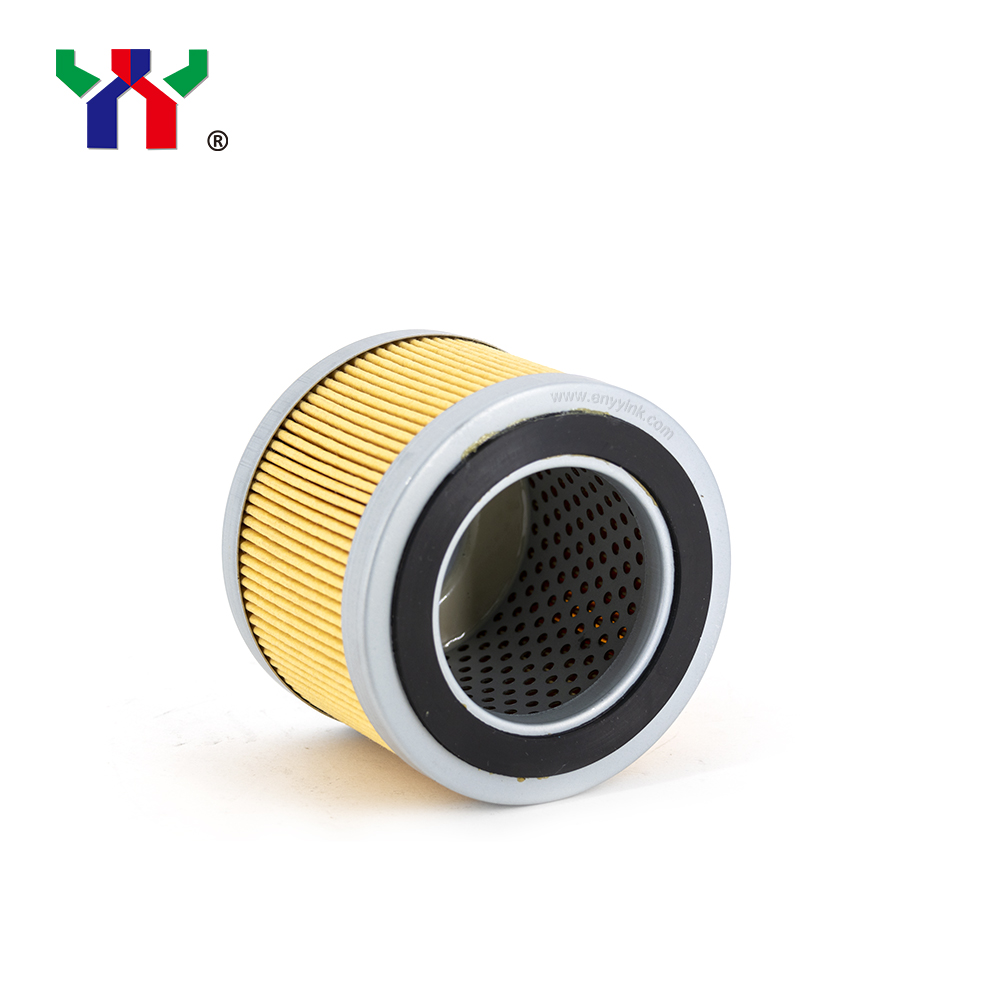

Air Filter (2)

maintenance

1. The filter element is the core component of the filter. It is made of special materials. It is a destructive part and requires special maintenance and maintenance;

2. When the filter has been working for a long time, the filter element has intercepted a certain amount of impurities, which will cause increased pressure and decrease in traffic. At this time, it needs to be cleaned in time;

3. When cleaning, be sure not to deform or damage the filter element.

Generally, according to the different raw materials used, the service life of the filter element is also different, but as the use time is extended, the impurities in the air will block the filter element, so generally speaking, the PP filter element needs to be replaced for three months; Replacement; and because the fiber filter element cannot be cleaned, it is generally used in the back-end of PP cotton and activated carbon, which is not easy to cause blockage; ceramic filter element can usually be used for 9-12 months.

The filter paper in the device is also one of the key. The filter paper in high -quality filter equipment usually uses ultra -fine fiber paper full of synthetic resin, which can effectively filter impurities and have strong pollution capacity. According to relevant statistics, a passenger car with an output power of 180 kW is driving at 30,000 kilometers, and the impurities filtered by the filtering equipment are about 1.5 kg. In addition, the equipment also has great requirements for the strength of the filter paper. Due to the large flow of air, the strength of the filter paper can fight against the strong airflow, ensure the efficiency of filtration, and extend the service life of the equipment.

Application field

1. In the machine tool industry, 85%of the machine tool transmission system uses hydraulic transmission and control. Such as grinding machines, milling machines, planes, pulled beds, pressure machines, cutting beds, and combined machine tools.

2. In the metallurgical industry, the control system of the electric furnace control system, the control system of the steel rolling machine, the flat furnace installation, the turntable control, the blast furnace control, the band bias and the constant tension device all use hydraulic technology.

3. In engineering machinery, hydraulic transmission is generally used, such as excavators, tire loaders, car cranes, crawler bulldozers, tires, and self -propelled tires, flat -ground machines and vibration rollers.

4. In agricultural machinery, hydraulic technology is also widely used, such as joint harvesters, tractors and plows.

5. In the automotive industry, hydraulic off -road vehicles, hydraulic downturn cars, hydraulic high -altitude operating vehicles and fire trucks all use hydraulic technology.

6. In the light textile industry, hydraulic technology uses plastic injection molding machines, rubber sulfids, papermaking machines, printing machines and textile machines.

Features

Modern automotive engines are becoming more and more common to use paper core air filters. So far, some drivers still have prejudice to the paper core air filter. It is believed that the filtering effect of the paper core air filter is not good. In fact, the paper core air filter has more advantages compared with the oil bath air filter: First, the filtering efficiency is as high as 99.5%(the oil bath air filter is 98%), and the use of dust is only the only thing of the dust is only the only thing. 0.1%-0.3%; the second is that the structure is compact and can be installed in any position without being limited by the layout of the vehicle's parts; the third is that it does not consume oil during maintenance, and it can save a lot of cotton yarn, felt and metal materials; the fourth is that it is to be the fourth is that Low quality and low cost. Therefore, the driver can use it with confidence.

The key to using the paper core air filter is to maintain its sealing performance, so as not to allow unique air to enter the engine cylinder from bypass.

Print Area is professional in printing industry 20+ years.

Security Paper:Watermark Paper,UV Fiber Paper,Thread Paper

Security Ink:OVI,UV Invisible Ink,Magnetic Ink,Water Sensitive Ink,Watermark Ink,Glow in Dark Ink

Offset Ink:Soy Bean Offset Ink,UV Offset Ink

Printing Materials:PS Plate,Rubber Blanket,Underpacking Foil,Underpacking Paper.

Machine:Die Cutting Machine,Offset Machine,UV Flexo Machine,UV Coated Machine ect.

Please don’t wait and contact with

Caroline:+8618026391301(wechat & whatsapp avaliable.)

Email:fluorescentink@yyink.com

Web:www.printarea.cn