-

05-10 2023

Production Method of Optical Variable Ink

Optically variable inks were first used in the anti-counterfeiting printing of banknotes, checks, bonds and other securities. With the continuous development of science and technology, optically variable inks are not only used for anti-counterfeiting printing of trademarks, but also for surface decoration of special products. The reason why the optically variable ink has the corner-changing color characteristic is that a pigment with a very special structure is used, and its particles are very thin flakes with a good particle size distribution. The production process of the pigment is as follows: under high vacuum conditions, according to the design requirements of a specific film structure, a variety of materials with different refractive indices are sequentially deposited on the same carrier to form an optically variable film, and then undergo crushing, grading, surface treatment, etc. . When the thickness of the film layer meets the interference conditions of light, the film layer will show a photochromic effect, that is, its color will change as the viewing angle of the human eye changes.

-

05-08 2023

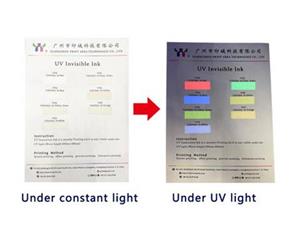

UV Invisible Ink: Preparation and Classification of UV Invisible Fluorescent Ink

Ultraviolet-excited fluorescent anti-counterfeiting ink is an ink made of inorganic pigments or organic dyes that can be excited by ultraviolet light to display colors, called fluorescent inks (or invisible inks). Its manufacturing method is to add the pigment (dye) to a certain proportion of resin oil linking material, filler, stabilizer and desiccant, and process it with an ink-making three-roller mill.

-

05-05 2023

Do you know the advantages of UV flexographic printing ink?

Flexographic printing is a type of letterpress printing that uses a flexographic printing plate and transfers ink through an anilox roller.

-

05-04 2023

First Container After Labor International Holiday

-

04-27 2023

What is Infrared Absorb Ink?

Infrared-absorbing anti-counterfeiting ink is made by adding one or several near-infrared absorbing materials into the ink. The infrared absorbing material is an organic functional dye. It has absorption in the near-infrared region, the maximum absorption wavelength is 700nm~1100nm, and the oscillation wavelength falls in the near-infrared region. Since the near-infrared absorbing ink absorbs infrared rays, if this ink is used in a certain part of the printed matter, there will be no damage in sunlight. Traces, but under the detection instrument, corresponding signals or dark pictures and texts can be observed.

-

04-25 2023

Do you know these characteristics of UV flexo printing inks?

-

04-24 2023

UV Flexographic Printing Ink Composition

Flexographic UV inks are mainly composed of prepolymers, reactive diluents, photoinitiators and sensitizers, pigments, and additives. According to the requirements of different printing materials, these components are reasonably coordinated to make the flexo UV ink achieve the best performance.

-

04-21 2023

Types and Characteristics of UV Ink

At present, UV ink is widely respected by printing manufacturers. And UV ink is an economical and environmentally friendly ink, which is the direction of ink development in the future. The types and characteristics of UV inks are introduced below.

-

04-18 2023

The Fifth China (Guangdong) International Printing Technology Exhibition (PRINT CHINA 2023) Grand Opening

-

04-04 2023

Is varnish and water-based paint the same paint?