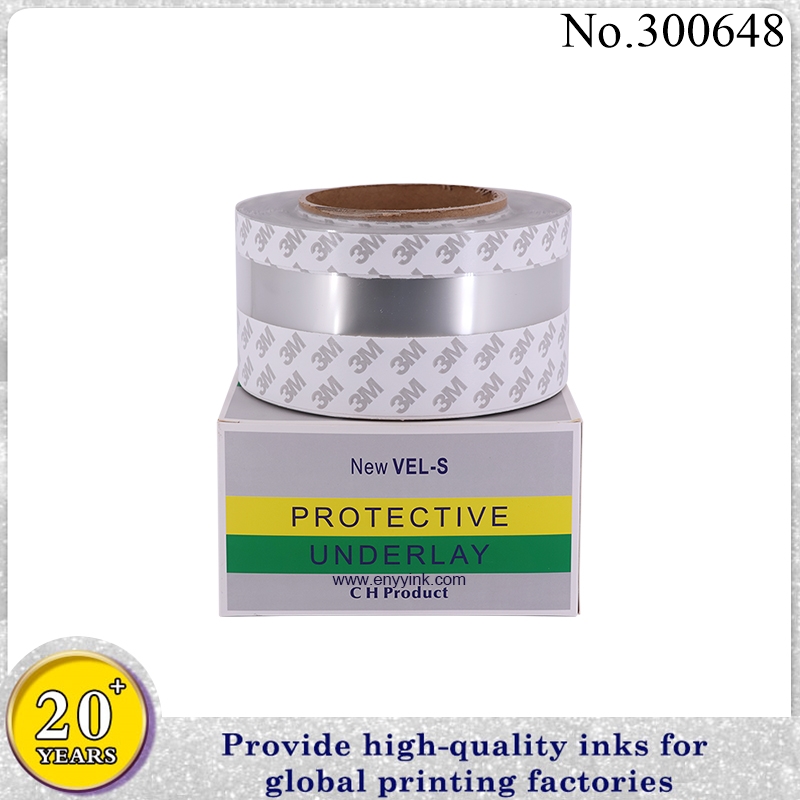

Best Quality 00.472.006 SM102 SM74 SM72 SM52 Protective Underlay Plastic 25Mx70MM for Heidelberg

Brand Inklove

Product origin Guangdong,China

Delivery time Within 3 Days

Supply capacity 10000 pcs

The protective underlay plastic you described (part number 00.472.006) is a specific wear and tear part for Heidelberg printing presses, particularly models SM102, SM74, SM72, and SM52.

Download

It's a long thin strip of plastic, 25 meters long and 70 millimeters wide, that serves as a protective barrier on the machine. Without it, the machine parts underneath would be more susceptible to scratches, dents, and other damage during operation.

You can find these underlay plastics from various suppliers, including Heidelberg themselves and after-market parts manufacturers. Be sure to check for compatibility with your specific Heidelberg press model before purchasing.

1. Product Description

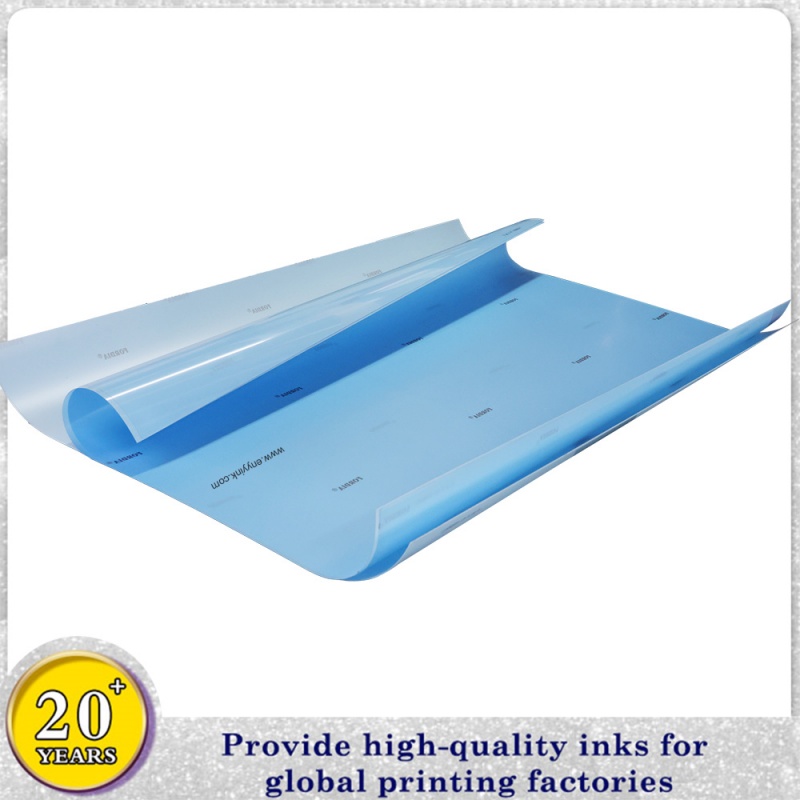

Specially designed for Heidelberg offset presses, this ink duct protection film shields the ink duct from drying ink, dust contamination, and metal corrosion. It ensures stable print quality, reduces cleaning downtime, and extends equipment lifespan.

2. Key Features

✅ Prevents Ink Drying – Minimizes ink exposure to air, reducing oxidation and skinning.

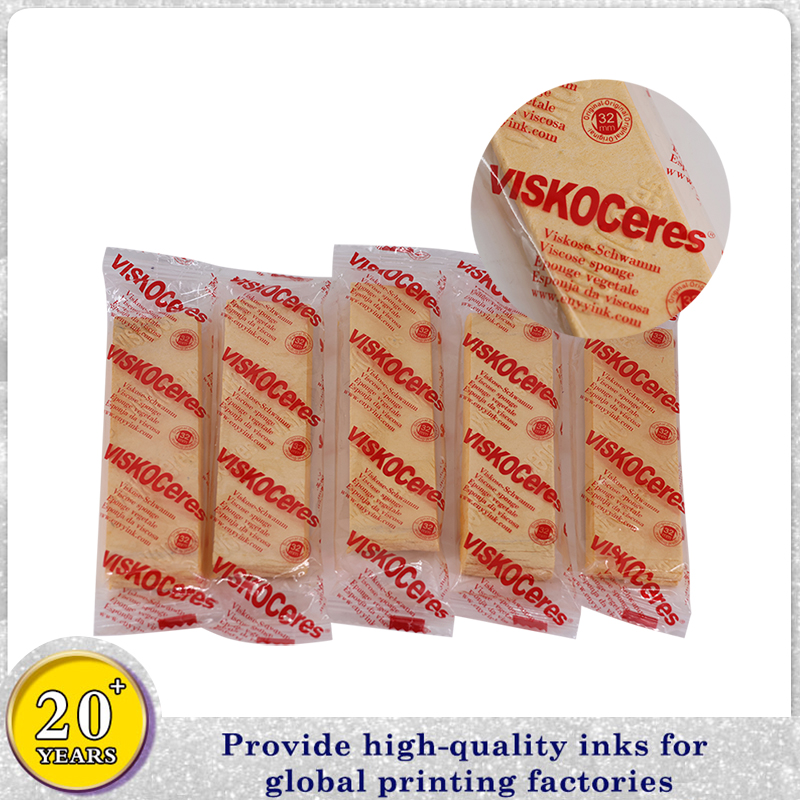

✅ Blocks Contaminants – Keeps paper dust and debris out of the ink system, maintaining consistent ink flow.

✅ Protects Metal Surfaces – Reduces ink-induced corrosion on the duct.

✅ Easy Maintenance – Quick film replacement cuts cleaning time and boosts productivity.

3. Compatible Models

Heidelberg Sheetfed Presses:

Speedmaster series: SM 52/74/102/CD/CX, etc.

Classic models: GTO, SM 72, PM 74

Ink Duct Types:

Traditional metal ducts

Automated ink systems with ink keys

4. Product Specifications

| Property | Details |

|---|---|

| Material | High-strength PET composite, resistant to ink corrosion and stretching |

| Adhesion | Low-residue adhesive, peel-off without surface damage |

| Ink Permeability | Micro-porous structure ensures unimpeded ink flow |

| Custom Sizing | Pre-cut or roll formats (common widths: 520mm/740mm/1020mm) |

| Temperature Range | Withstands pressroom conditions (-10°C to 60°C) |

5. Installation Guide

Clean the Duct: Remove residual ink with a spatula; wipe with alcohol.

Apply the Film: Cut to match duct width and lay flat over the surface.

Remove Air Bubbles: Use a squeegee to ensure full adhesion.

Resume Printing: The film dissolves gradually with ink use (some variants require periodic replacement).

6. Customer Benefits

Cost Savings: Reduces ink waste by 15–30% by preventing drying.

Higher Efficiency: Less washup time increases productive uptime.

Quality Assurance: Eliminates dried ink particles that cause ghosting or streaks.

7. Industry Applications

Packaging Printing: Ensures color consistency for long runs (e.g., cigarette/liquor boxes).

Commercial Printing: Ideal for catalogs and magazines requiring precision.

Newspaper Printing: Minimizes wash frequency for short runs.

8. vs. Generic Films

| Feature | Heidelberg-Specific Film | Generic Film |

|---|---|---|

| Material | Ink-resistant, non-dissolving | Prone to ink erosion/perforation |

| Fit | Precision-engineered for Heidelberg ducts | Requires trimming, may peel |

| Ink Flow | Micro-pores maintain flow | May interfere with ink keys |

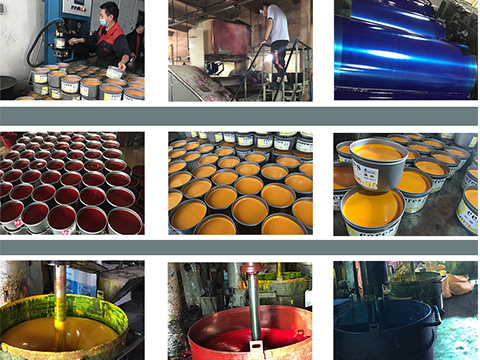

ABOUT PRINT AREA

Founded in 2004,Print Area Technology Co. ,Ltd has our own professional ink R&D Department. We have developed high-quality eco-friendly offset ink, printing plates (PS & CTP Plate), printing material,printing machine spares, blanket and so on. We focus on printing industry and help our customers solve their printing problem. We serve and lead the local printing industry.

Print Area is professional in printing industry 20+ years.

Security Paper:Watermark Paper,UV Fiber Paper,Thread Paper,

Security Ink:OVI,UV Invisible Ink,Magnetic Ink,Water Sensitive Ink,Watermark Ink,Glow in Dark Ink

Offset Ink:UV Offset Metal Ink,Soy Bean Offset Ink,UV Offset Ink

Printing Materials:Rubber Blanket,Underpacking Foil,Underpacking Paper.

Machine:Die Cutting Machine,Offset Machine,UV Flexo Machine,UV Coated Machine ect.

Please don’t wait and contact with

Caroline:+8618026391301(wechat & whatsapp avaliable.)

Email:fluorescentink@yyink.com

www.printarea.cn

Proofing is usually 3-5 working days.If you order reach or exceed behind MOQ quantity,proofing fee refunded.If not reached behind MOQ quantity,proofing fee will be taken by you....more