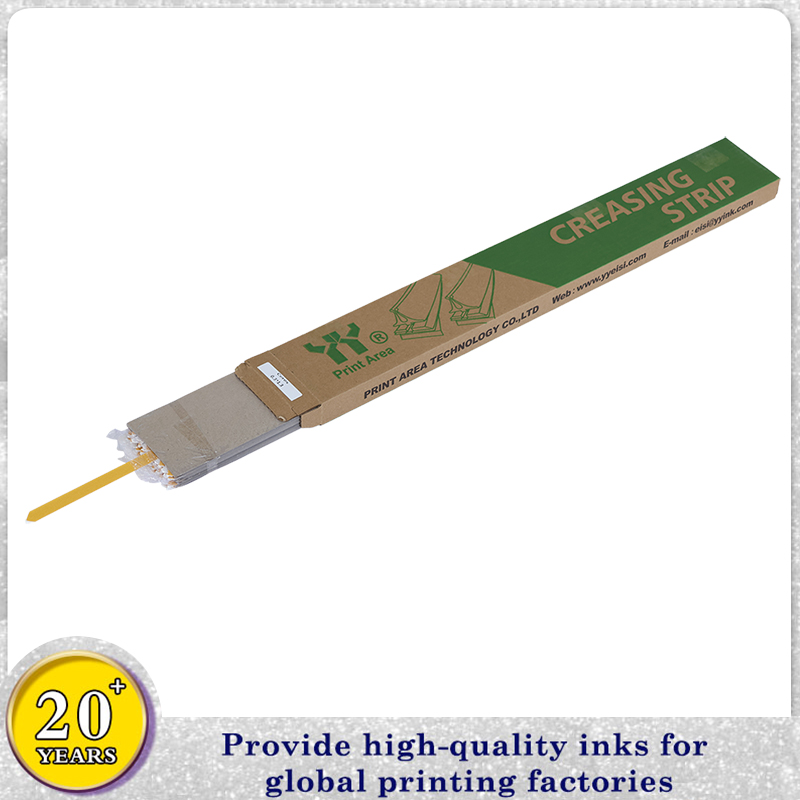

High Precision Creasing Matrix Strip, 0.5mm 0.6mm 0.7mm 0.8mm Cutting Creasing Rule, Long Life Die Cutting Matrix for Corrugated Carton Box Printing

Brand EISI

Product origin Guangdong,China

Delivery time Within 3 Days

Supply capacity 200-1000pcs/week

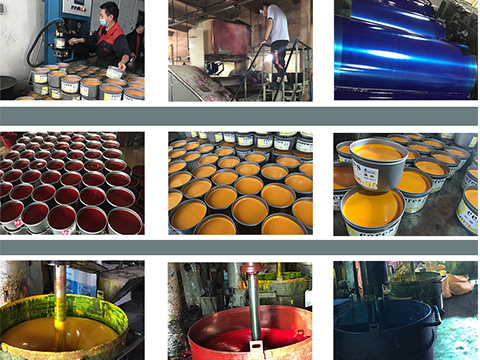

Forged from 20 years of specialized experience in printing consumables manufacturing, our Precision Series High-Accuracy Creasing Matrix is a core component designed for professional printing and packaging plants worldwide. Understanding that a perfect crease is critical to final product quality, we are committed to providing high-quality products for global printing factories. We infuse superior materials and precise craftsmanship into every strip, ensuring it delivers sharp, consistent, and crack-free creases even under high-speed die-cutting pressure.

Download

1. Product Overview

Forged from 20 years of specialized experience in printing consumables manufacturing, our Precision Series High-Accuracy Creasing Matrix is a core component designed for professional printing and packaging plants worldwide. Understanding that a perfect crease is critical to final product quality, we are committed to providing high-quality products for global printing factories. We infuse superior materials and precise craftsmanship into every strip, ensuring it delivers sharp, consistent, and crack-free creases even under high-speed die-cutting pressure.

2. Key Features & Benefits

Proven Reliability: Backed by 20 years of supplying quality products to the global printing industry, we deeply understand the needs of various equipment and materials. This creasing matrix embodies our technical expertise, offering dependable and consistent performance.

Exceptional Material & Durability:

Made from Imported High-Strength Polyurethane (PU): Selected top-grade raw materials offer extreme abrasion and tear resistance.

Extended Service Life: Outstanding wear resistance significantly outperforms standard market products, reducing replacement frequency and machine downtime, thereby lowering your overall operational costs.

Precision Engineering for Perfect Creases:

High-Precision CNC Machining: Ensures minimal tolerances in height and thickness for a perfect fit with cutting rules and counter plates, eliminating misalignment or issues like "crushing."

Smooth Edge Finish: Finely polished edges are smooth and burr-free, protecting paper fibers from damage and preventing cracking or bursting on the crease line, ideal for high-end color printing.

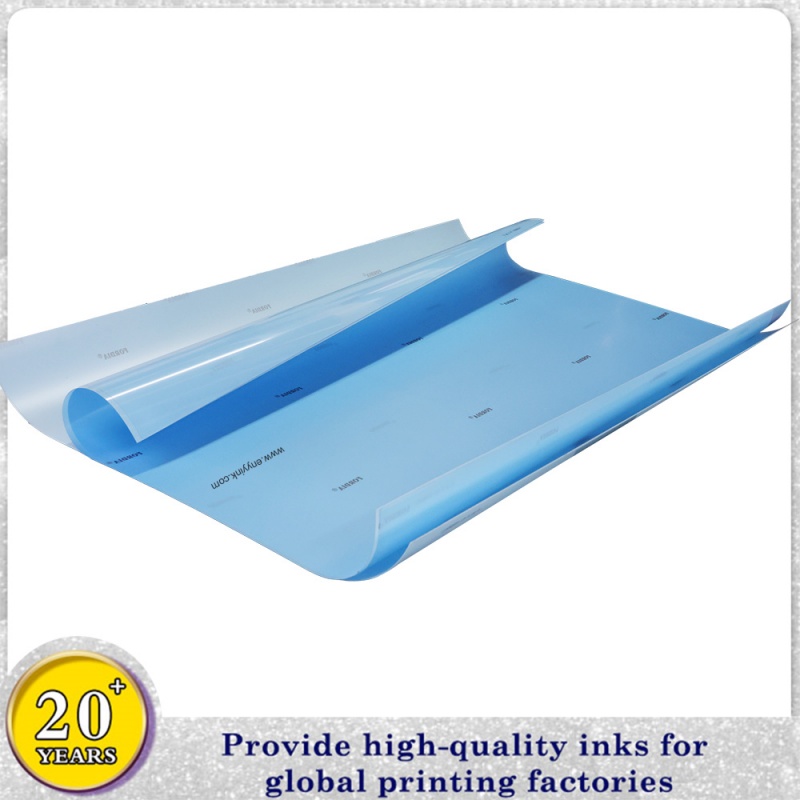

Wide Compatibility & Easy Operation:

Comprehensive Specifications: Available in various standard heights and thicknesses (e.g., 0.5mm, 0.7mm, 1.0mm, 1.42mm), compatible with major die-cutting machines like BOBST, Heidelberg, Masterwork, Xuhong.

Easy Installation: Precise dimensions ensure quick and easy mounting, minimizing setup time and boosting productivity.

3. Technical Specifications

Parameter Details

Primary Material Imported High-Strength Polyurethane (PU)

Standard Height Customized to fit shim/plate height (e.g., 23.8mm, 23.5mm)

Standard Thickness 0.5mm, 0.7mm, 1.0mm, 1.05mm, 1.42mm, etc.

Hardness 92°±2° Shore A (High hardness, suitable for high pressure)

Color Transparent/Amber (For easy visualization and installation)

Packaging Industrial standard packaging, dust and moisture resistant

| Card Paper GSM | Thickness | Steel Height | Creasing Matrix (0.71 Steel) | Creasing Matrix (1.05 Steel) |

| 150 | 0.21mm | 23.60mm | 0.2*0.8 | …… |

| 200 | 0.28mm | 23.50mm | 0.3*1.0 | …… |

| 230 | 0.32mm | 23.50mm | 0.3*1.2 | …… |

| 250 | 0.35mm | 23.50mm | 0.3*1.3 | …… |

| 300 | 0.42mm | 23.40mm | 0.4*1.3 | …… |

| 350 | 0.50mm | 23.30mm | 0.5*1.5 | …… |

| 400 | 0.56mm | 23.30mm | 0.5*1.6 | …… |

| 450 | 0.63mm | 23.20mm | 0.6*1.7 | 0.6*1.9 |

| 500 | 0.70mm | 23.10mm | 0.7*1.7 | 0.7*2.1 |

| 550 | 0.77mm | 23.00mm | 0.8*1.9 | 0.8*2.3 |

4. Applications

Ideal for a wide range of applications requiring precise creasing:

High-End Packaging: Luxury gift boxes, cosmetic boxes, wine cartons, electronics packaging.

Bookbinding: Hardcover book covers, premium notebooks, menus.

Commercial Printing: High-quality brochures, foldable cards, greeting cards, invitations.

5. Our Commitment

Choosing our creasing matrix means partnering with a reliable provider with 20 years of experience. We promise:

Consistent and Reliable Quality

Competitive Pricing

Professional and Responsive Technical Support

Fast and Efficient Logistics

Let our 20 years of expertise create the perfect first fold for your products!

Proofing is usually 3-5 working days.If you order reach or exceed behind MOQ quantity,proofing fee refunded.If not reached behind MOQ quantity,proofing fee will be taken by you....more