Inklove YF-303 Water Based Flexo Ink

Brand Inklove

Product origin Guangzhou,China

Delivery time 7-15 working days

Supply capacity 50 ton per one month

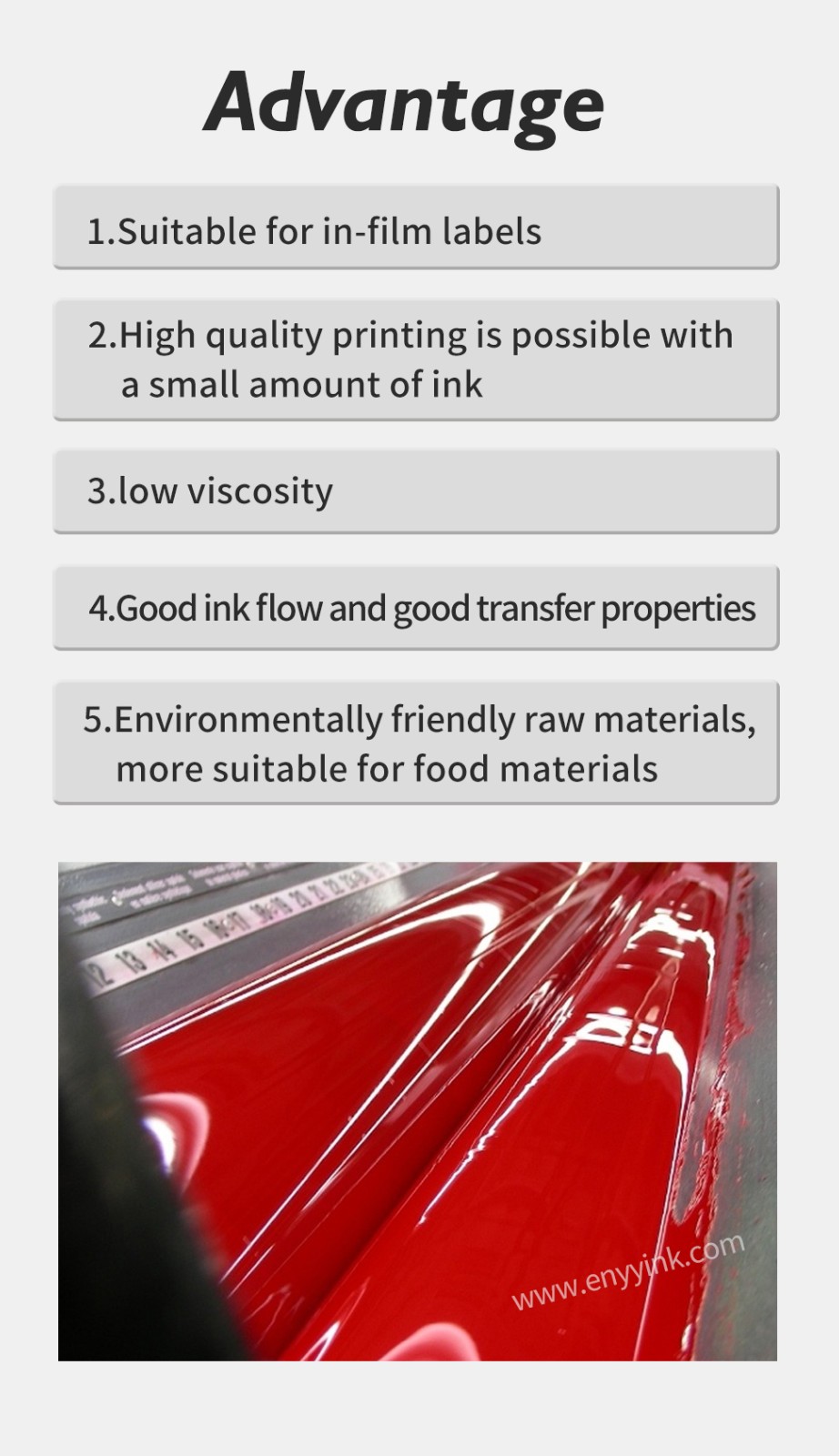

The special ink used by the flexographic printing machine is water-based ink. It has the advantages of no pollution to the environment, no impact on human health, non-flammable, good safety, stable ink performance, bright colors, no corrosion of the plate, simple operation, and price Cheap, good post-printing adhesion, strong water resistance, rapid drying, printing speed can reach 150~200m per minute. It is precisely because of the above characteristics that flexo water-based inks are especially suitable for the printing and use of packaging and decoration printing products such as food, medicine, cosmetics, etc., which require strict sanitary conditions.

Download

YF-303 Water Based Flexo Ink

Water-based uv flexo ink package:5kg/barrel,20kg/barrel

Main indicators of flexo water-based ink

1. Fineness

Fineness is a physical index that measures the particle size of pigments and fillers in the ink, and is directly controlled by the ink manufacturer. The user generally understands it, and the size cannot be changed during use. The fineness of flexographic water-based ink is generally below 20μm, and the instrument for measuring fineness is a fineness squeegee.

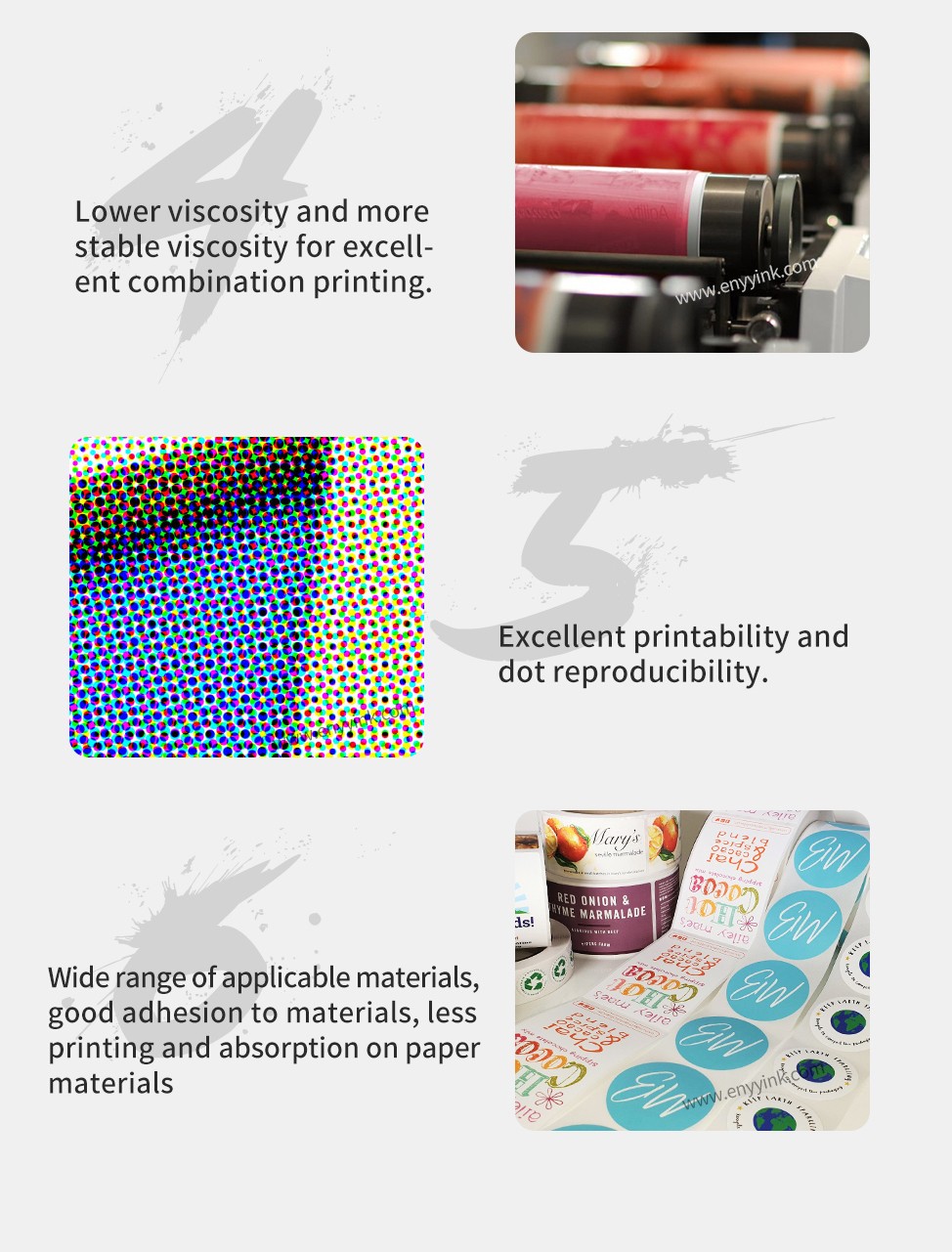

2. Viscosity

Viscosity is one of the main indicators of water-based ink. The value of viscosity will directly affect the quality of printed matter. Therefore, the viscosity of water-based ink should be strictly controlled in flexographic printing. The viscosity of water-based ink is generally controlled within the range of 30-60 seconds/25°C (with paint No. 4 cup), and the viscosity is generally controlled within 40-50 seconds. If the viscosity is too high, the leveling will be poor, which will affect the printability of the water-based ink, and easily lead to dirty plates, paste plates, etc.; if the viscosity is too low, it will affect the carrier's ability to drive the color.

If the water-based ink is left for a long time, some inks with poor stability are prone to sedimentation and delamination, and some will have false thickening. At this time, sufficient stirring can be carried out, and the above problems can disappear naturally. When using fresh water-based ink, be sure to mix well in advance before making dilution adjustments. During normal printing, the ink fountain should also be stirred regularly.

Water-based inks are easy to freeze at temperatures below 0°C. If the water-based ink freezes, it can be placed in a room with a high temperature to let it dissolve naturally, and it can be used after it is evenly stirred. When the temperature difference between winter and summer is large, the viscosity is most sensitive. When the temperature is high, the moisture evaporates quickly, and the drying is also fast. When operating, pay attention to reducing the drying time or increasing the machine speed; when the temperature is low, the moisture evaporates slowly and the water-based ink dries slowly, which can increase the drying of the water-based ink during operation. Speed or add drying device. When using in winter, it is best to put the water-based ink stored in the warehouse in the workshop in advance to balance the viscosity.

3. Dry

Drying is one of the most important indicators in water-based inks, because the drying speed is the same as the viscosity, which can be directly reflected in the quality of the printed matter. The operator must have a detailed understanding of the drying principle in order to rationally adjust the drying time of the water-based ink according to the product or substrate. While ensuring that the water-based ink is dried well, it must also be considered that the viscosity is moderate or the pH value is stable.

The drying of water-based ink includes three methods: volatilization, absorption and reactive solidification. After the water-based ink prints are thoroughly dried, they have strong water resistance and abrasion resistance. If it dries too fast, the surface of the ink layer is easy to crust, and the water-based ink is easy to dry on the printing plate, resulting in dirty plates, unclear patterns around, and inability to remove internal moisture, which may cause inaccurate overprinting. It can be adjusted with a retarder. It can be solved by increasing the speed of the printer or turning off the drying system. When stopping, it is best to clean the anilox roller or ink fountain. When stopping for a short time, also often stir the ink fountain to prevent surface skinning; drying too slowly, the paper stretches and reduces gloss, which will affect the multi-color printing and may cause adhesion , Bring a lot of trouble to the machine operators. At this time, you should first check whether the pH value is correct. According to the pH value, add stabilizers or ethanol in an appropriate amount to adjust to make the water-based ink dry faster.

4. PH value

Water-based ink contains a certain amount of ammonium solution, which is used to improve its stability or enhance the water resistance after printing. Therefore, the pH value is one of the important indicators. The pH value of water-based ink when it leaves the factory is generally controlled at around 9. The pH value used by the machine can be adjusted or controlled between 7.8 and 9.3

It should be flexibly controlled according to the different substrates and temperature. At the same time, the relationship between dryness and viscosity should be considered, and various additives should be added in an appropriate amount to adjust. The pH value of gold ink should not be too high and can be controlled between 8 and 8.5 to make it slightly alkaline. Generally check once every 2 to 3 hours, and adjust as soon as possible, try to control the pH value within the best printing suitability range.

Storage of Water-based UV Flexo Ink

The shelf life of flexographic water-based inks is generally one year, beyond the shelf life or longer. As long as there is no solidified colloidal state, only surface layering or precipitation, as long as it is fully stirred, it can be used continuously. The storage temperature should be within the range of 5℃-30℃. It is best to store in a warehouse, not in the open, not exposed to the sun, and not in a warehouse below 0°C. The shelf life of gold ink is half a year or less.