Screen Printing Optical Variable Magnetic Ink Purple to Green

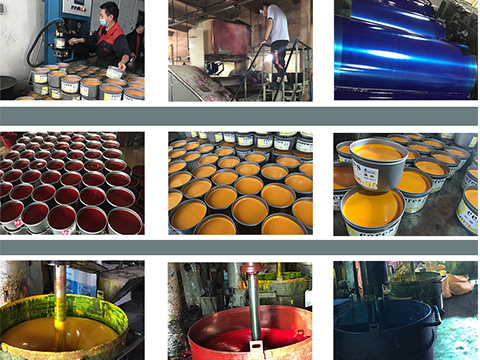

Brand Inklove

Product origin Guangzhou,China

Delivery time 7-15 working days

Supply capacity 50 ton per one month

Optically variable magnetic ink is more magnetic than optical variable ink, but it was very different.

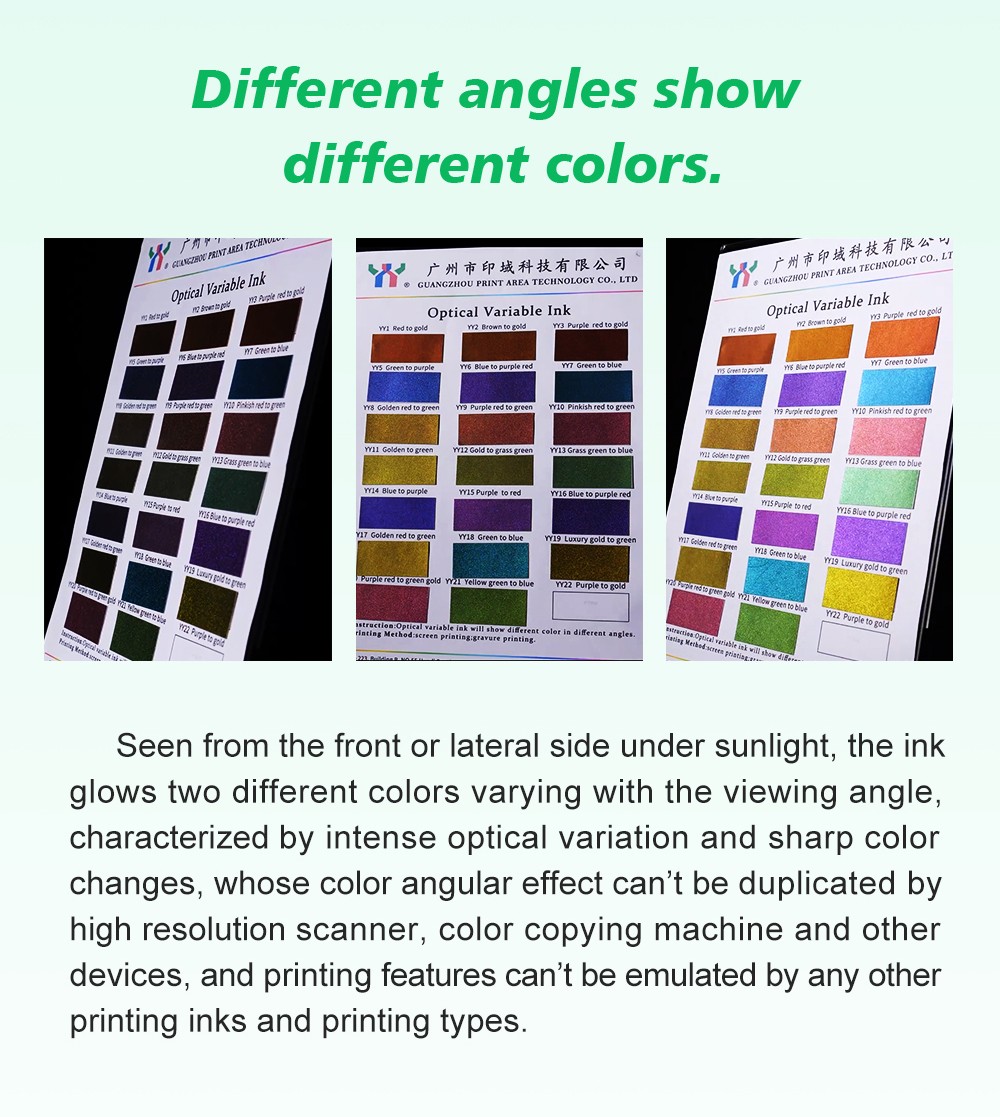

When the viewing angle changes, the light and dark of the image in the area will shift, and the effect of flow will occur at the same time, during which the color will gradually change. What it embodies is unique and dynamic.

Download

Screen Printing Optical Variable Magnetic Ink

1. Product Overview

Screen-Printable Magnetic Optical Variable Ink (MOVI) is an advanced anti-counterfeiting ink that combines magnetic properties with angle-dependent color-shifting effects, delivering dual-layer security:

Optical color shift: Dynamic color transition when viewed from different angles (e.g., gold→green→blue).

Magnetic response: Machine-readable magnetic patterns detectable via specialized sensors.

Widely used in banknotes, passports, securities, and luxury packaging, MOVI is recognized as a top-tier anti-counterfeiting solution globally.

3D magnetic optically variable ink: The printed color block printed by magnetic optically variable ink presents a pair of color changes. When viewed from the front or side under white light, it presents two different colors with the change of the viewing angle of the human eye. Under the action of a specific magnetic field, the magnetic powder wrapped by the magnetic light-changing raw material is oriented and arranged with the action of the magnetic field, forming a specific light-changing effect, such as 3D cat's eye, three-dimensional beam effect, etc. The effect printed by magnetic optical variable ink has strong optical variable characteristics, large color difference changes, and obvious features. It can be recognized without any equipment. Its color angle effect cannot be reproduced by any high-definition scanners, color copiers and other equipment. The printing features cannot be imitated by any other ink and printing method, and the anti-counterfeiting reliability is extremely strong, so it is designated by many countries in the world for the most demanding and difficult anti-counterfeiting of currency and securities, and is also used in packaging anti-counterfeiting .

2.Product parameters:

| Original Place: | Guangdong,China | Brand: | Inklove | Item No.: | YY |

| Anti-counterfeiting principle | Interference principle | Net Weight | 100g;1kg | Tinting power | 100% |

| Fineness | 20μm | Viscosity | 30s | Fluidity | ≥ 25mm |

| Dryness | ≤ 15 | Fixation speed | ≤ 100min | Shelf life | 1 year |

| Color | See Color Sheet | Hazardous chemicals or not | No | Best printing method | Silk screen printing, gravure printing |

| Applicable Object | Screen printing, gravure printing, transfer printing, pad printing, spraying (drying method UV or self-drying) | ||||

Anti-counterfeiting principle

(1) Anti-counterfeiting principle of 3D magnetic light-changing ink

Inks made of magnetic optically variable pigments are called magnetic optically variable inks. The printed product effect after fixed magnetic curing under a specific magnetic field. The sun shines on the surface of the product. Using the principle of optical interference, the 3D stereoscopic effect and color changes can be seen by deflecting the product angle.

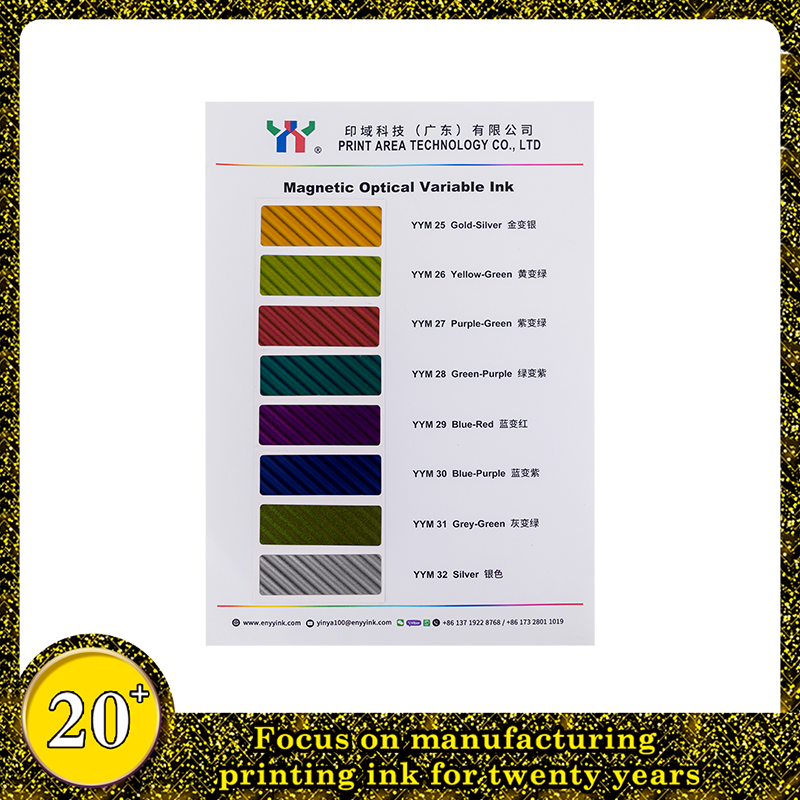

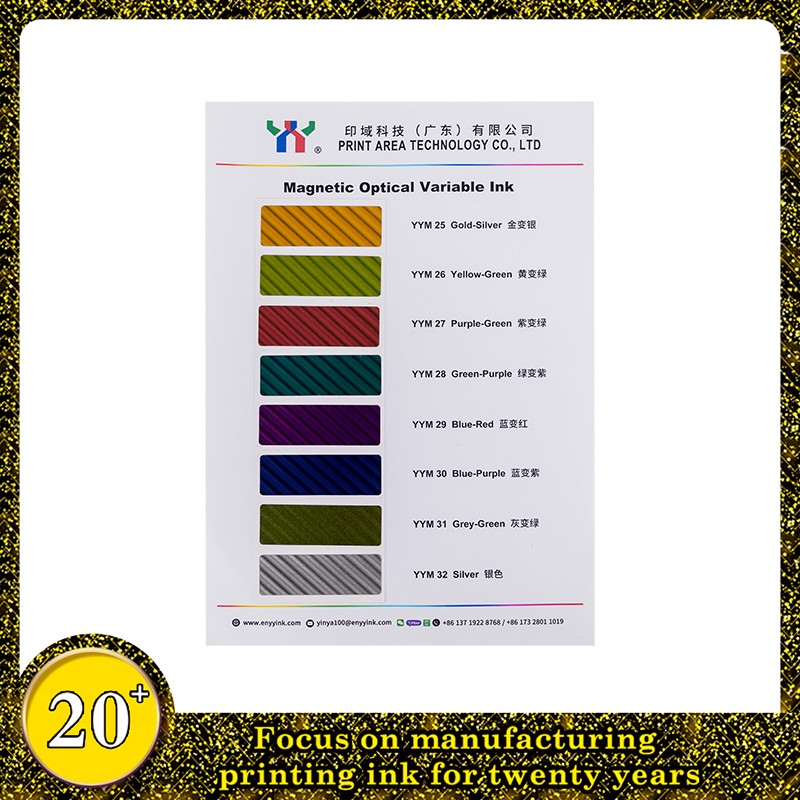

3. Color-Shift & Magnetic Combinations

Standard Options:

Gold↔Green + Magnetic encoding

Purple↔Blue + Magnetic dot matrix

Customization:

Tailored color-shift paths (Pantone-matching available).

Adjustable magnetic signal strength (weak/medium/strong).

4. Applications

✅ Currency Security: Hidden magnetic codes on banknotes (e.g., Euro serial numbers).

✅ Document Protection: Machine-readable zones (MRZ) in passports.

✅ Luxury Branding: Color-shifting logos + magnetic traceability for premium packaging (wine/cosmetics).

✅ Industrial Authentication: Anti-counterfeit labels for high-end electronics/auto parts.

5. Printing Guidelines

Substrate Preparation:

Paper/plastics require primer (enhances magnetic particle adhesion).

Metal surfaces must be degreased.

Screen Parameters:

Recommended: 200-300 mesh polyester/stainless steel screens.

Magnetic ink layer ≥15μm (ensures signal strength).

Curing Methods:

UV curing (energy ≥1000mJ/cm²) or thermal curing (80°C × 20 mins).

6. Verification & Detection

Optical Check: Visual inspection of color-shift effects.

Magnetic Detection:

Generic magnetic sensors (confirm presence).

High-precision readers (decode embedded data).

7. Competitive Advantages

| Criteria | MOVI | Standard OVI |

|---|---|---|

| Security Layers | Optical + magnetic dual-auth | Optical-only |

| Machine-Readable | Yes (magnetic decoding) | No |

| Replication Difficulty | Extreme (requires nano-magnetic materials) | High (needs thin-film interference tech) |

8. Precautions

⚠️ Magnetic Interference: Keep printing environment away from strong magnetic fields.

⚠️ Storage: Seal in dark, dry conditions (<30°C) to prevent magnetic decay.

⚠️ Design Confidentiality: Magnetic pattern locations/encoding must be strictly controlled.

Custom Solutions:

Magnetic encoding design (ISO 7811 compliant).

Integration with holographic foiling, QR codes for multi-layer security.

Printing method:

Screen printing, gravure printing, transfer printing, pad printing, spraying and other methods.

Printing material:

Paper, cloth, metal, glass, ceramic, plastic and other materials.

Drying method:

Self-drying, UV curing.

Applications

Currency, financial bills, cards, anti-counterfeiting marks, etc.

More information about the security ink,please kindly contact us:

Contact Name:Caroline Lin

Email:fluorescentink@yyink.com

Tel:+8618026391301

Proofing is usually 3-5 working days.If you order reach or exceed behind MOQ quantity,proofing fee refunded.If not reached behind MOQ quantity,proofing fee will be taken by you....more